If there is one area where blockchain continues to find prominence and support, it is in supply chains. And the reasons are obvious: the promise of unmatchable transparency and traceability as well the ability to bring down administrative overheads through automation.

Simply put – Blockchain automates trust among entities in the supply chain. What does that mean? The supply chain participants don’t have to trust each other. Trust is enabled by technology. Now if the problem of mistrust is solved, the supply chain could be exposed to a plethora of benefits – product traceability, counterfeits prevention, improved compliance, and cost-effective delivery of products.

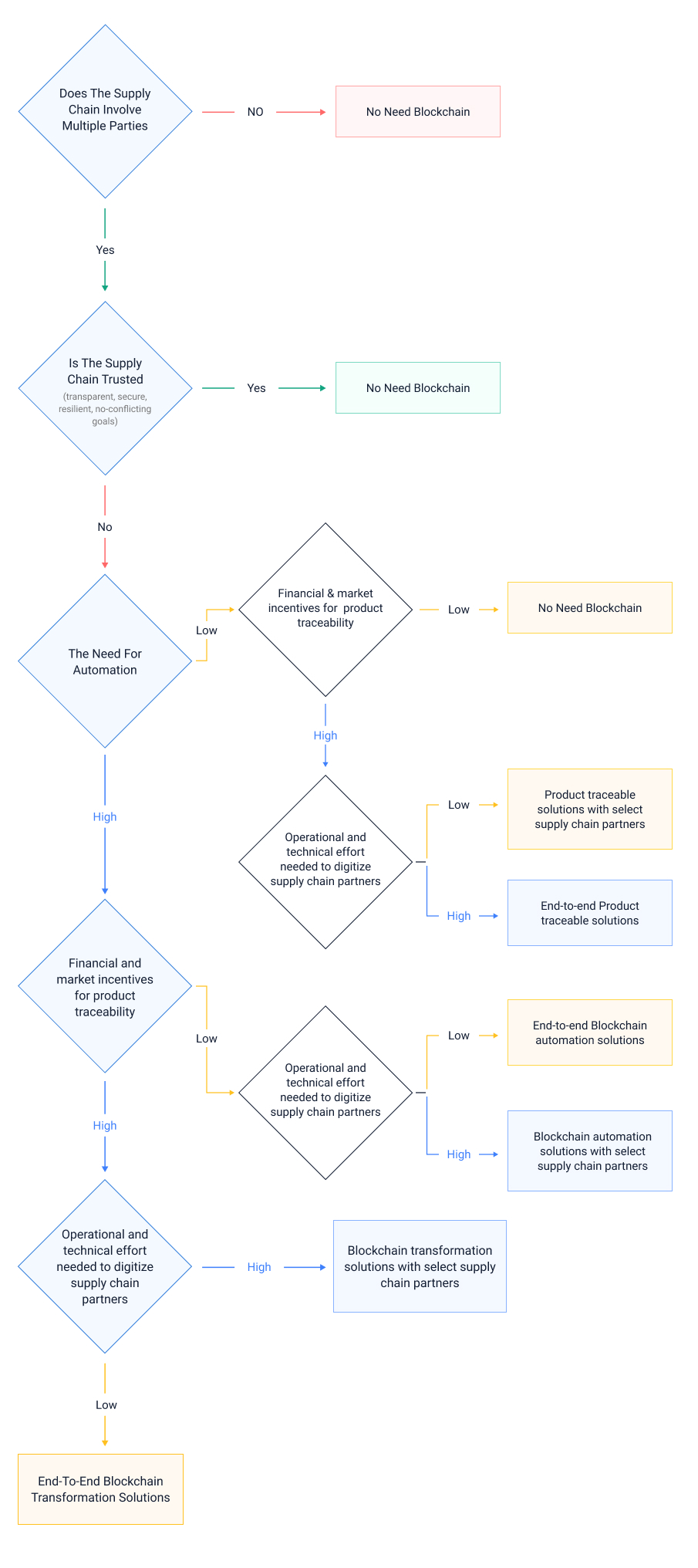

Now, this begs the question, is blockchain mandatory for all supply chains? Is it a must or maybe? When and where does it really work? And finally, of all networks does your supply chain network need blockchain?

And so, here we are with a blueprint on blockchain for the supply chain. This would help understand when blockchain would really work. Much better, what type of blockchain solution would suit your value chains.

Case 1: Trusted Supply Chains

When your supply chain involves few and known parties, chances are that you don’t need blockchain. Why? Because they can be trusted. But what do we mean by trust in the context of supply chains? Trust must be measured with respect to the following four factors.

a. Security

The ability to anticipate, identify, monitor, and prevent threats that may affect the continuity of supply chains.

b. Transparency

The business clearly knows what is happening at every stage of the supply chain. The business has full visibility across all the nodes in the supply chains.

c. Resilience

In the event of a supply chain disruption, the ability of the business to see through a particular node that is affected, make contingency plans, and mitigate shocks.

d. No-conflicting goals

The goal to maximize their own operational performance at the cost of partners’ operational performance. Operational performance includes flexibility, product quality, and production costs.

Case 2: The need for automation

What is automation in the context of supply chains? You must see what flows across your supply chain.

- Inventory flows

- Financial flows

- Information flows

Does automating the above flows maximize productivity and translate to higher profitability? Will it result in a significant reduction of operating costs?

Blockchain automation corresponds to immutable recordkeeping and the implementation of smart contracts. Smart contracts are simple blockchain programs that get triggered when certain conditions are met. When a contractual agreement resides on a smart contract, it gets immediately enforced when the pre-defined criteria are met without the need for human intervention.

A case in point – Automated payments between manufacturer and supplier. Both the parties could set up digital wallets and a smart contract is in place to pay the supplier automatically upon the receipt of goods.

Case 3 – Financial & market incentives for product traceability

Is the market ready to pay a premium to prove the provenance of a product?

Is the market plagued with an unscrupulous supply of counterfeits?

What are the sale value losses from fake goods?

The time, cost, and effort required to satisfy compliance and regulation demands?

Blockchain track and trace solutions enable digital tracking of real products through appropriate product identifiers. By placing a supply chain on blockchain, the stakeholders can instantly trace the origin or the exact location of the actual product in question.

A case in point – Within the supply chain of a global retail player, probable food contamination would at least take two weeks to locate the source of contamination. A blockchain product traceable solution enables faster detection of the affected source and targeted product recalls. The global retail player now takes seconds to locate the source of affected mangoes.

Case 4 – Operational and technical effort needed to digitize supply chain actors

What are the technical and operational challenges to the rollout of blockchain-enabling technologies across supply chain partners?

Do the supply chain actors have limited technological capacity?

Do they have a standardized approach to tracking data or labeling products?

What’s the level of digital maturity of the supply chain both upstream and downstream?

A case in point – In the tracking of processed beef in Brazil, it needs significant effort to introduce blockchain-enabling technologies at the farm level. The cattle producers are low-tech. Introducing traceability and RFID technology to track individual animals could be a challenge. As of now, the animals are only tracked in groups and manually documented (GTA). These animals use multiple farms before slaughter. Significant work is required to digitize CAR (farm compliance with forest code) and GTA (mandatory animal transit guide) and further efforts to identify individual animals from groups.

Solution 1: Blockchain Automation Solution

Blockchain automation solution is best suited in industries where there are few financial and market incentives for product traceability, but a supposedly higher need for automation of inventory, financial and information flows that could bring down sizeable operational overheads and maximize productivity.

The solution is based on an immutable ledger that records the flow of information, money, and inventory in real-time. The ledger is distributed across participants. All participants can view the data with permissioned access. Every transaction is chronologically entered, timestamped, and tamper-proof, meaning the information cannot be altered. Thus, the history of a transaction is completely visible and fool-proof, leaving no room for fraud.

Example: Covantis is a consortium of agri-business companies coming together to simplify and fasten global post-trade execution. The post-trade execution remains highly complex with manual repetitive and costly time-consuming operations. The initiative focuses on the reduction of paper-based processing and the amount of email exchanged between parties. The solution is powered by an immutable ledger that records transactions (inventory, money, and information) and is shared in real-time across participants.

Now what problems does it solve? How does this translate to operational efficiency?

- Reduced need for manual re-entry and review

- Seamless information exchange between participants

- Secure and auditable transactions

- Reduced manual errors and the risk of fraud or data manipulation

- Reduced operational risks associated with storage, shipping, and wait times

If immutable recordkeeping is one part of blockchain automation, then smart contracts are a step higher; they enable automated transactions, minimize human intervention, cut down reliance on intermediaries, and reduce operational overheads.

Example: US-based insurer, StateFarm and the United States Automobile Association Financial Services group have entered a partnership to use a blockchain-based Ethereum solution for the exchange of subrogation claims in auto insurance. Subrogation is a claim by which, in an accident, the insurance company of the victim can claim to ask for payouts from the insurance company of the driver at fault. What blockchain essentially does here is it maintains a single source of truth of all transactions made between StateFarm and USAA. Instead of manually settling each claim, it tallies all the claims made between them and executes one net transaction after a period of time. Thus, saving a lot of operational costs and enabling both the companies to perform automated transactions without ceding control to a third party.

Solution 2: Blockchain Traceable Solution

Blockchain traceable solutions would be applicable in places where the need for automation is not as high as an impending need to prove product integrity. The solution best works where there is a pressing need to track and trace products owing to globalized supply chains, diverse suppliers, counterfeit risks, and end-consumer demand for product visibility.

In pharmaceuticals, there is a deliberate threat from falsified products as well as from innocent errors directly tied to the safety of patient lives. Falsified and substandard medicines contribute to thousands of deaths, especially in poorer countries. The DSCSA Act requires the supply chain participants (manufacturers, repackagers, wholesale distributors, and suspensers) to enable product tracing at the package level by 2023.

Ensuring end-to-end traceability begins with product authentication technology. In pharmaceuticals, there are spectrometer analyzers to inspect the products at the ingredient level. Serialization involves adding a unique identifier to sellable product units. At the package level, SDNC (serialized national drug code) serves as standard numerical identifiers for packaged drugs. The drug would pass a series of checks until they reach the patient. The federated codes that identify the product would be stored in an immutable ledger, time-stamped, unalterable, and provide a single source of truth for all the participants. At the end of the supply chain, the patient or the caregiver can scan the unique barcodes and check for the provenance of the drug.

In the case of product falsification or contamination, the blockchain can enable identify the root cause of the issue – find out at which point the contamination has occurred, enable faster, targeted product recalls, provide all relevant data to regulators, and thus instill confidence in the marketplace and with consumers.

Solution 3: Blockchain Transformation Solution

All blockchain solutions rest on an incorruptible truth ledger shared among stakeholders. The difference is in the objective. If blockchain automation is all about process and efficiency, and blockchain traceable solutions revolve around the product and its visibility, then blockchain transformation solution will be a combination of the above and would focus on both product and process.

The solution best applies where there is a pressing need for accurate recordkeeping, provenance tracking, bringing down administrative overheads, and pursuing lower costs – automotive industries are a classic case in point. The automotive landscape is undergoing a period of transition from manual and gasoline-powered vehicles to autonomous and electric cars that can connect and transact with each other. To support this rapid digitization, the supply chains must evolve quickly, become dynamic, and pave way for improved synergy across the value chain.

Blockchain transformation solutions in automotive would cover the full nine yards from manufacturing to delivery. Both the inbound and outbound supply chains involve a complex network of globally distributed suppliers, regulatory agencies, importers, distributors, and dealers. These participants manage their own databases and hence do not have a common consensus with respect to data. This leaves room for components counterfeiting, redundant and repetitive processes, and spare parts duplication. Remember, while the assembly itself takes very little time, procuring the car parts from different suppliers takes months because of the manual processing involved, complex paperwork, siloed databases spread across countries and suppliers. This is just inbound logistics. Similar process uncertainties exist in outbound logistics as well.

So, what problems does the blockchain transformation solution solve?

- A seamless decentralized information-sharing platform where information concerning every auto part procured is accessible at the click of a button.

- A blockchain-enabled digital identity solution for streamlined supplier onboarding. The supplier details will be captured and stored in the blockchain. Once verified, the supplier can provide their supplies, and payments would be executed automatically once the order is fulfilled.

- An end-to-end supply chain solution that enables an automotive organization to order, track, buy, sell, and pay for goods arriving at their destination. Documents would be created, updated, and accessed in real-time. Payments could be automated based upon agreements written on smart contracts. This could be between buyers and sellers, sellers and custom agencies, and sellers and shipping agencies.

- Product tracking facility that brings together service center, car manufacturer, and customer on one platform. The customer can trace the origin of a spare part through the supply chain and verify its manufacturing date.

- A blockchain-based solution for manufacturers to identify and recall defective parts. Since the information about products is stored on an immutable ledger, once the manufacturer identifies the faulty products and flags them on the ledger, the supplier is duly notified of the defect and can plan contingency action.

- A combination of IoT and blockchain tech to certify mileage data and prevent odometer frauds.

Before you commit

It is to be noted that in certain supply chains, automation, traceability, and transformation may not be feasible end-to-end. The digital maturity of the supply chain actors, especially at the production level must be taken into consideration. In such a case, blockchain solutions with select supply chain partners could still be a viable solution.

Stay tuned to this space for more insights on blockchain for supply chains.

Interested in blockchain solutions for your supply chain? Talk to blockchain experts at Blockedge.

Joe Arputhan Writer, researcher, content marketing evangelist, and blockchain enthusiast. |